Optimized mold designs for superior plastic products.

Designing plastic parts is a complex task involving several parameters that address a list of requirements of the application. How is the part to be used? How does it fit to other parts in the assembly? What loads will it experience in use? What is its application? What are the dimensional and tensile requirements? Does the part need to withstand elements, pressure, chemicals? Does this part meet our requirements for volume and size?

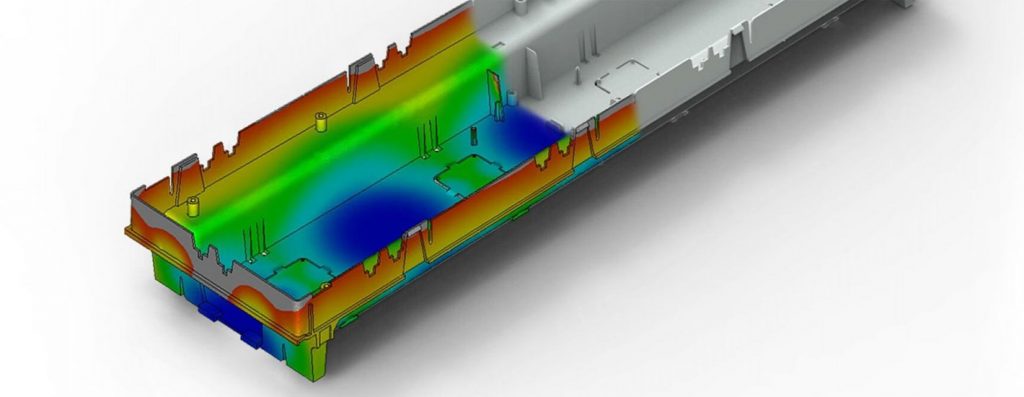

In addition to functional and structural issues, processing issues play a large role in the design of an injection molded plastic part. How the molten plastic enters, fills, and cools within the cavity to form the part largely drives what form the features in that part must take. Trend Offers;

Rapid prototyping of parts to support design and development

Selection of the optimum performing engineered resins

Advanced applications, including mold flow and warp analysis for difficult parts or critical-to-function parts

Our product mold design team are experts in leading mold design and analysis software packages such as Unigraphics NX and Solidworks.